THE STRONGEST MATERIAL IN THE WORLD TO HEAT AND WEAR

THE STRONGEST MATERIAL IN THE WORLD TO HEAT AND WEAR

ABOUT US

OUR MISSION

Equip vehicles with the Strongest Material to Heat and Wear.

OUR VISION

Help in creating a safer and sustainable future.

QUALITY POLICY

Safe and effective solutions for industrial sector with a global approach.

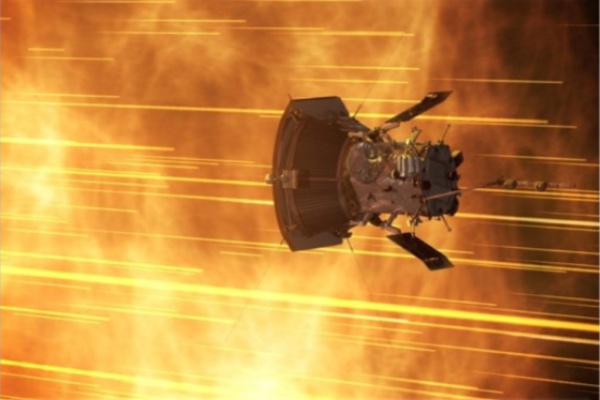

Our primary business is to offer components for space market and High / Hyper Speed Transport replacing current products, with the most resistant materials in the world at temperature and wear.

Our products have been invented for thermal protection systems of the next generation of hypersonic vehicles and rocket motor inserts (nozzle, chamber etc) of satellite launchers, demonstrating to perform much better than conventional ones and showing superior durability.

We want to create something very rare in the industrial sector, a deep-tech startup focused on solving a very complex and specific problem, but with enormous impact in the market. With its innovative products, K3RX is well on its way to becoming a worldwide leader in extremely hot and harsh environment applications.

PRODUCTS

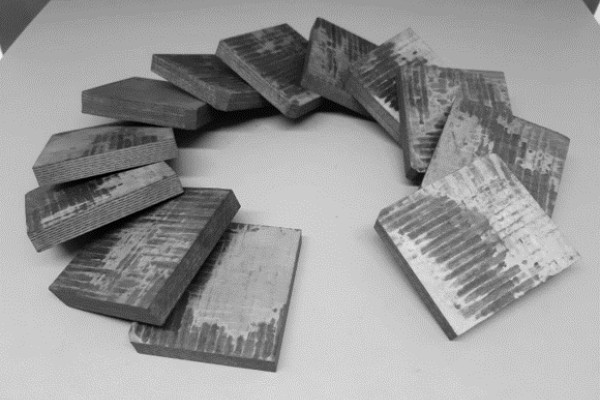

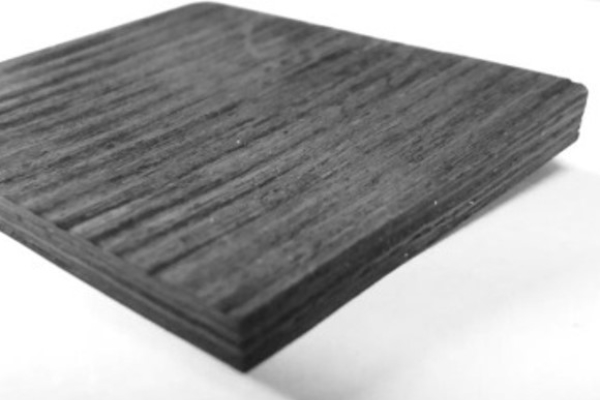

TILES

K3RX manufactures tiles in UHTCMC material, e.g tiles forming the Thermal Protection System (TPS) of hypersonic vehicles that should resist the stresses during launch and re-entry into Earth’s atmosphere. Manufacts can be produced into various shapes with high dimensional accuracy. Fiber orientation can be adjusted according to customer need.

ROCKET NOZZLES

K3RX is manufacturer of erosion resistant rocket nozzles for the aerospace industry (hybrid and solid propellant propulsion). Made from UHTCMC materials. Capabilities include machining via EDM on the base of customer drawing. Other services such as finishing, engineering and research or development are also available.

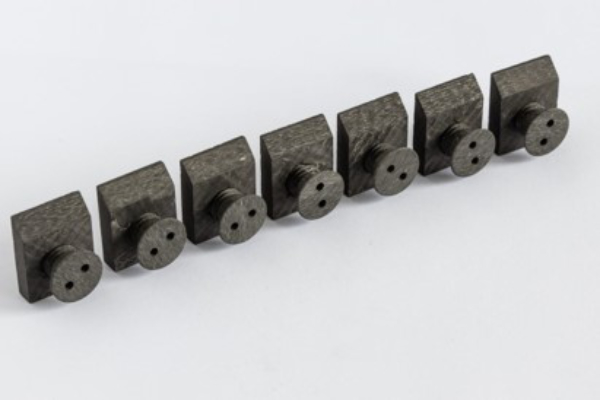

MECHANICAL CONNECTORS

Screws, nuts and supports as mechanical connectors able to withstand temperature above 1500 ˚C keeping their mechanical strengths under those extreme conditions are machinable from UHTCMC blocks. Benefits of the material include higher durability, low-deformability and less need of replacement, maintenance or adjustment.

MATERIALS

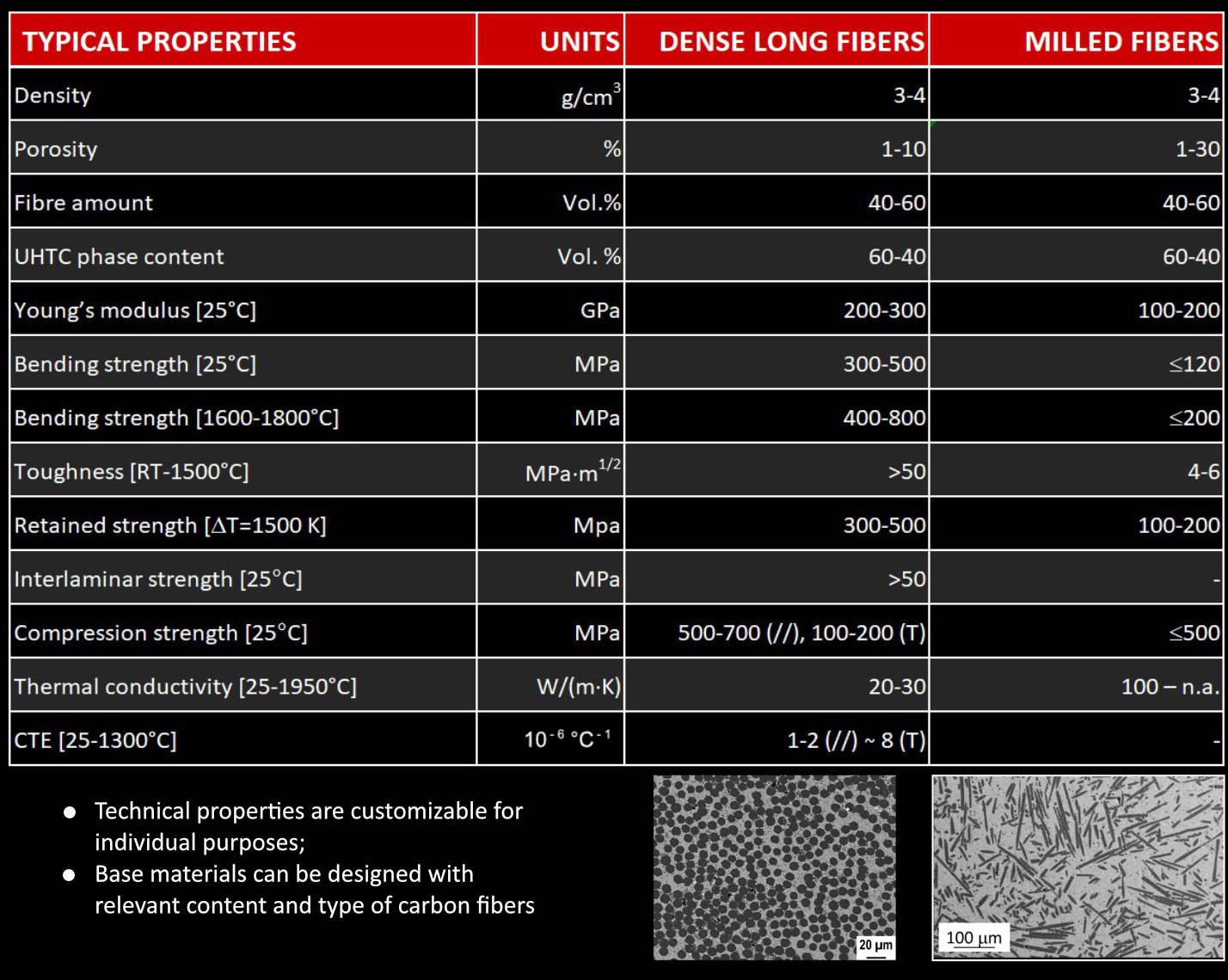

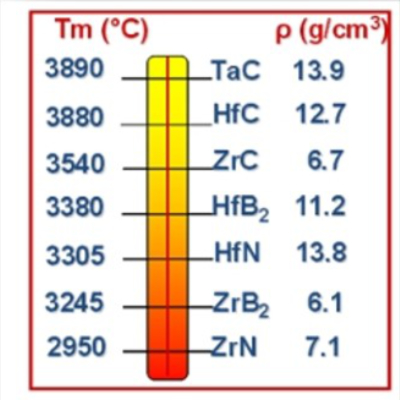

Carbon fiber reinforced Ultra-High Temperature Ceramic Matrix Composites (UHTCMCs)

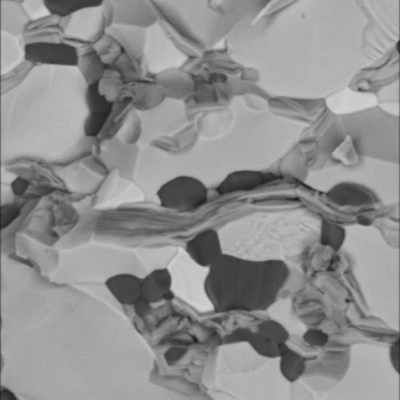

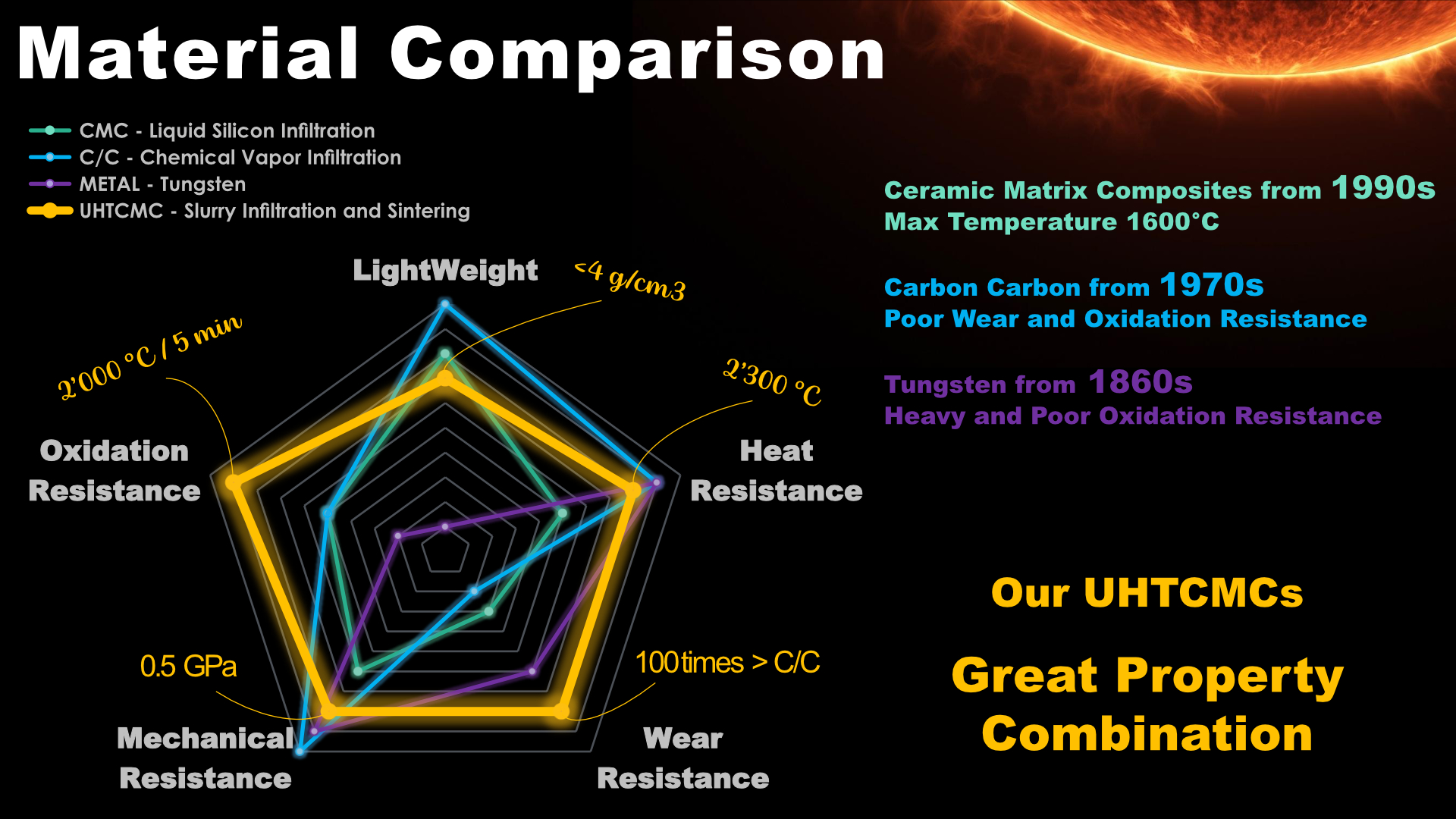

K3RX products originate their amazing properties from carbon fiber reinforced ultra high temperature ceramic matrix composites (UHTCMCs) – an innovative class of materials which combine the superior erosion/ablation resistance of Ultra-high temperature ceramics (UHTCs) at extreme hot and harsh environments and advantages of current ceramic matrix composites (CMCs) such as toughness, thermal shock resistance and damage tolerance.

- Non-brittle behaviour

- High resistance to most corrosive and abrasive media

- Adjustable properties to meet specific customer requirements

- Excellent thermal shock resistance

- Near zero ablation above 1800 °C.

- Self-healing capability

GREENER

In the space sector K3RX offers products with enhanced properties without production of pollutant particulate during manufacturing and serving, as required for the next generation re-suable space vehicles.

CHEAPER

It can be envisaged that these components will resist several launches and re-entries thus allowing a vehicle to undergo several missions in his lifetime, with notable cut in manufacturing costs.

BETTER

K3RX is able to produce an innovative class of materials which combine the superior erosion/ablation resistance of ultra-refractory ceramics in extremely hot and harsh environments with thermal shock resistance and damage tolerance typical of C/C

FASTER

K3RX process is fast thanks to the innovative process of manufacturing. Moreover K3RX products are machinable by EDM technology that is time and material saving compared to diamond tools methods.

TAILORED

- Mechanical properties

- Lightness

- Passivation capability

K3RX products are highly customizable because the matrix formulation can be adapted to customers needs.

COMPARED TO C/C and C/SiC

- High ablation resistance

- High erosion resistance

- High electrical conductivity

- Low porosity

COMPARED TO REFRACTORY METALS

- Lightweight (1/5 of tungsten)

- High heat resistance

- Low thermal expansion

- Excellent resistance to chemicals

COMPARED TO GRAPHITE

- High strength and rigidity

- High ablation resistance

- High erosion resistance

MARKETS

AEROSPACE

From space exploration missions, led by government agencies to space economy, K3RX is expected to have economic, social and environmental positive impact, primarily on space sector.

TRANSPORT

K3RX proposes high performance automotive components, including racing clutches and brakes. By using UHTCMC technology, K3RX can assist in boosting performance for high tech vehicles or energy efficient heat-treating supplies.

METALLURGY

Fixture systems undergo tremendous heat loads during heat treatment processes. K3RX fixtures and components are ideal for this application and absolutely maintenance free. The cost benefits will be enormous compared to current solution.